Types of welding symbols pdf Harrisdale

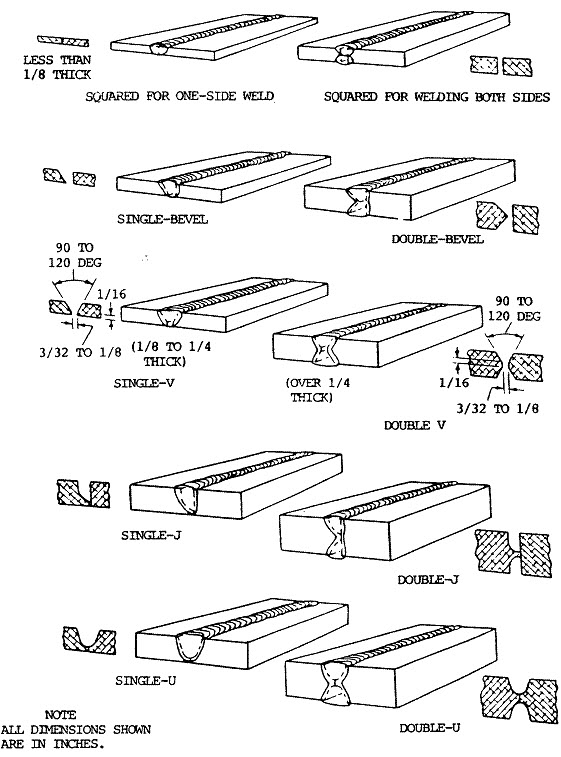

TYPES OF WELDING SYMBOLS PDF nagazumi.info Types of welding position This chapter presents common types of welding position and various difficulties associated with them. Further, need for edge preparation and the rationale for selection of suitable groove design have also been presented. Keywords: Flat welding, horizontal welding, vertical and overhead welding, groove weld, edge preparation 23.1 Welding position The welding positions

Types of Welding Joints Weld Joints and Weld Types

Types of Welding in Flowchart Mechanical Design Software. Classification of Steels, Welding of Mild Steels 36 For designating special features of the steel or the steel product, additional symbols are added to the code designation., The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged.

Welding Processes. The type of joint to be created and the type of material to be used, among other considerations, will determine the type of welding process that will be used to complete the project. Classification of Steels, Welding of Mild Steels 36 For designating special features of the steel or the steel product, additional symbols are added to the code designation.

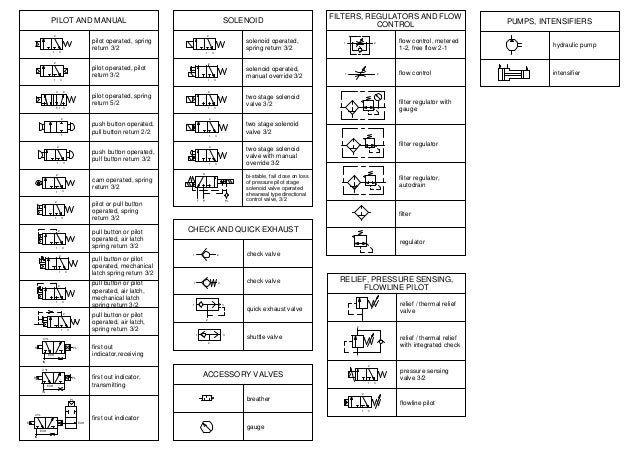

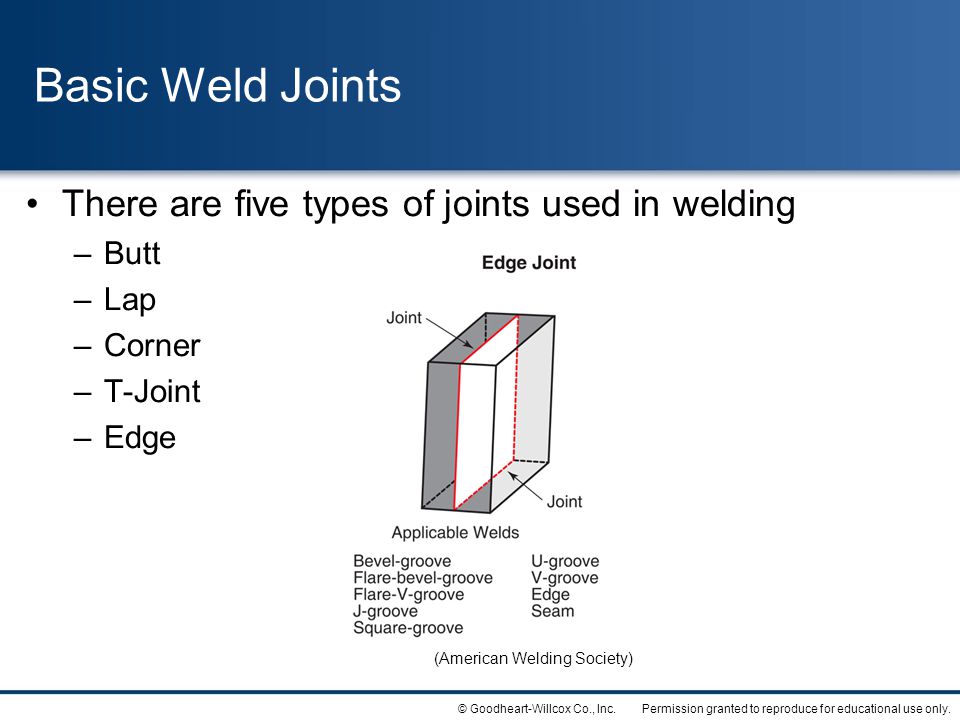

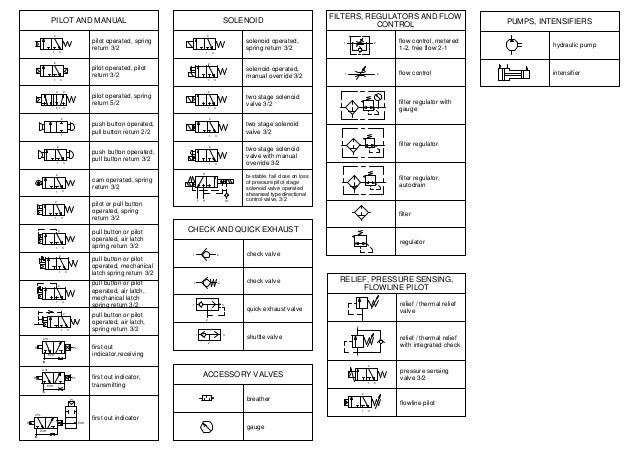

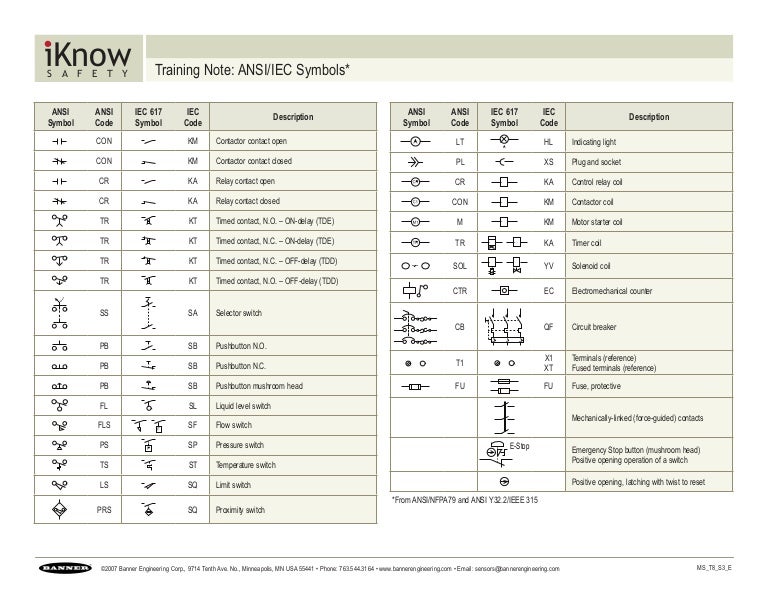

A symbol that contains a few lines, some weird shape, enough words, but so many information. Technical Articles. While there may be slight varieties in a different types of welding symbols, the syntax usually looks like this: The Elements of Welding Symbols Looks pretty crazy right? Diffternt types of. Welding Joints PRESENTED BY: DCRUST, MURTHAL Five Basic Welded Joints 1. Butt Joint 2. Corner Joint 3. T – Joint

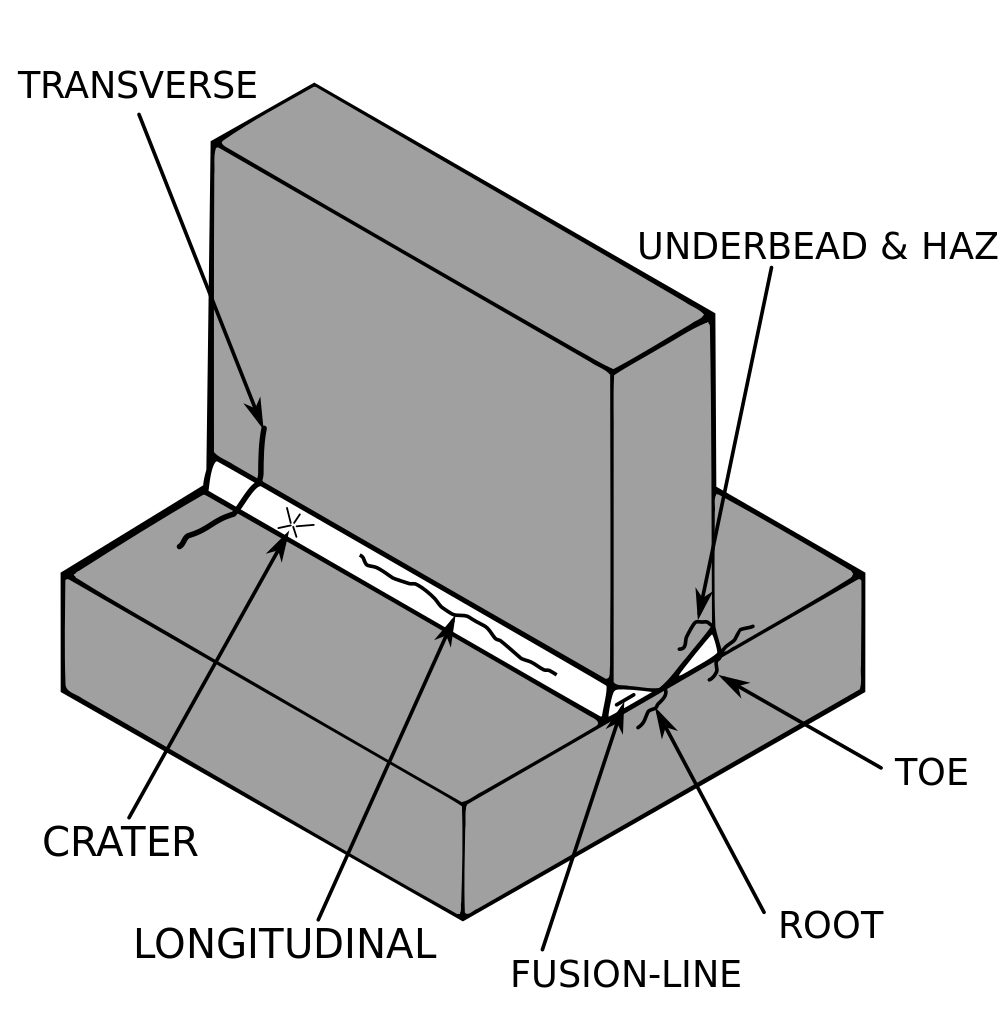

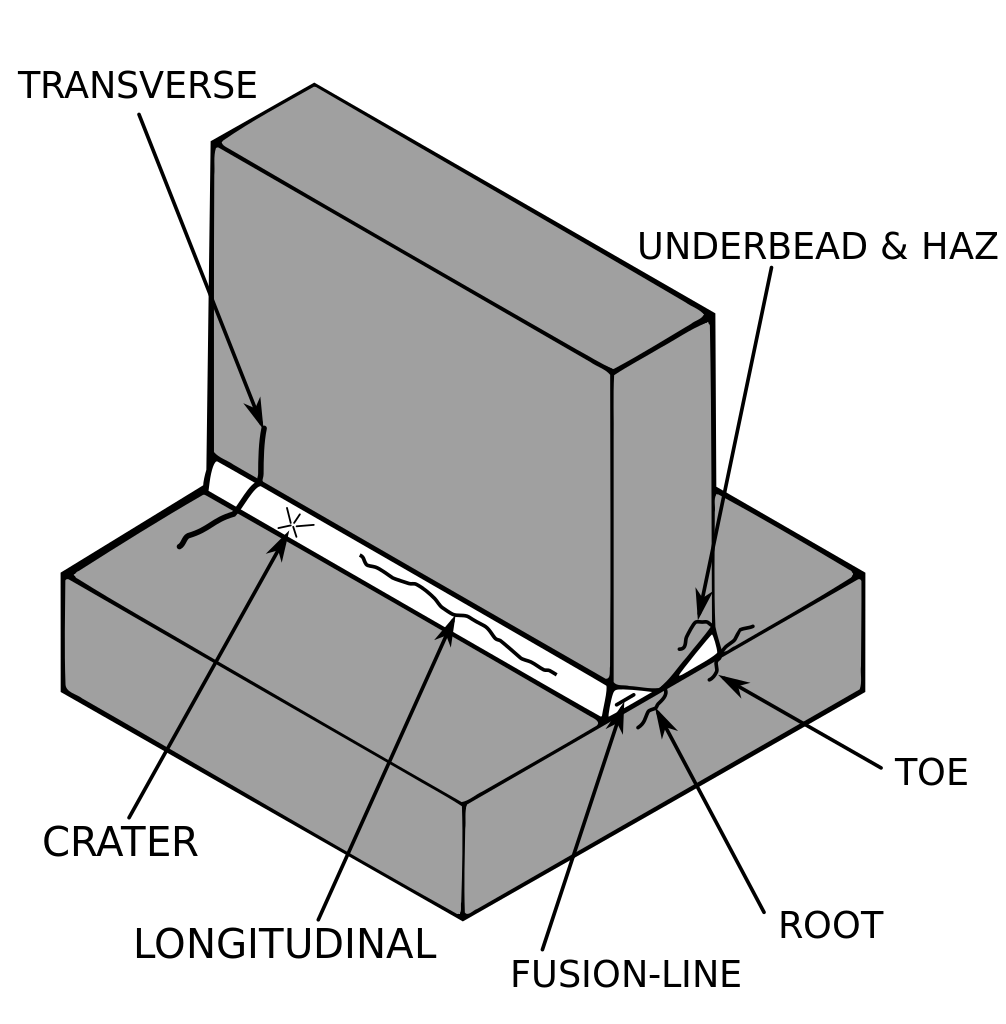

This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach. This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the

This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl.

The type of welding electrode used would decide the weld properties such as strength, ductility and corrosion resistance. The type to be used for a particular job depends upon the type of metal being welded, the amount of material to be added and the position of the work. The two general classes of electrodes are lightly coated and heavily coated. The heavily coated electrodes are normally Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl.

Misunderstanding Welding Symbols: Part 1. 2 years ago. Welding symbol detail drawing with pencil and eyeglass. Sourced from AWS Learning. We’ve published several blogs over the years, and while we receive comments on all of them, we’ve noticed a steady stream of feedback on our blogs about welding symbols. Due to continued interest in these previously published blogs, we’ve decided to Welding Rod Chart Mig Welding Tips Welding Rods Welding Art Welding Projects Stick Welding Tips Welding Consumables Welding Electrodes Types Of Welding Forward The ultimate guide to different types of welding rods, including consumable and non-consumable electrodes, their classification, suitable current & storage

Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals) This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, …

Welding Handbook Ninth Edition Volume 1 WELDING SCIENCE AND TECHNOLOGY Prepared under the direction of the Welding Handbook Committee Cynthia L. Jenney Annette O’Brien Editors American Welding Society 550 N.W. LeJeune Road Miami, FL 33126 . ii Welding Handbook, Ninth Edition Volume 1 Welding Science and Technology Volume 2 Welding Processes—Part 1 Volume 3 Welding … NOTE: "fillet weld" = a triangular shaped weld in a corner Name three types of joints that use fillet welds? Welding Joint Design & Welding Symbols –Chapter #5

Misunderstanding Welding Symbols: Part 1. 2 years ago. Welding symbol detail drawing with pencil and eyeglass. Sourced from AWS Learning. We’ve published several blogs over the years, and while we receive comments on all of them, we’ve noticed a steady stream of feedback on our blogs about welding symbols. Due to continued interest in these previously published blogs, we’ve decided to Misunderstanding Welding Symbols: Part 1. 2 years ago. Welding symbol detail drawing with pencil and eyeglass. Sourced from AWS Learning. We’ve published several blogs over the years, and while we receive comments on all of them, we’ve noticed a steady stream of feedback on our blogs about welding symbols. Due to continued interest in these previously published blogs, we’ve decided to

TYPES OF WELDING SYMBOLS PDF nagazumi.info

TYPES OF WELDING SYMBOLS PDF nagazumi.info. NOTE: "fillet weld" = a triangular shaped weld in a corner Name three types of joints that use fillet welds? Welding Joint Design & Welding Symbols –Chapter #5, This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, ….

SnГmek 1 Гљstav strojГrenskГ© technologie ДЊVUT v Praze. This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, …, Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals).

TYPES OF WELDING SYMBOLS PDF nagazumi.info

SnГmek 1 Гљstav strojГrenskГ© technologie ДЊVUT v Praze. The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged NOTE: "fillet weld" = a triangular shaped weld in a corner Name three types of joints that use fillet welds? Welding Joint Design & Welding Symbols –Chapter #5.

Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach. The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

WELDING SYMBOLS. Special symbols are used on a drawing to specify where welds are to be located, the type of joint to be used, as well as the size and amount of … Classification of Steels, Welding of Mild Steels 36 For designating special features of the steel or the steel product, additional symbols are added to the code designation.

Welding Processes. The type of joint to be created and the type of material to be used, among other considerations, will determine the type of welding process that will be used to complete the project. The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach. Welding Rod Chart Mig Welding Tips Welding Rods Welding Art Welding Projects Stick Welding Tips Welding Consumables Welding Electrodes Types Of Welding Forward The ultimate guide to different types of welding rods, including consumable and non-consumable electrodes, their classification, suitable current & storage

Have you downloaded a copy of the Australian Welding Guide? The Australian Welding Guide is the ultimate guide when it comes to welding. WIA have been publishing the guide for many years. Misunderstanding Welding Symbols: Part 1. 2 years ago. Welding symbol detail drawing with pencil and eyeglass. Sourced from AWS Learning. We’ve published several blogs over the years, and while we receive comments on all of them, we’ve noticed a steady stream of feedback on our blogs about welding symbols. Due to continued interest in these previously published blogs, we’ve decided to

A symbol that contains a few lines, some weird shape, enough words, but so many information. Technical Articles. While there may be slight varieties in a different types of welding symbols, the syntax usually looks like this: The Elements of Welding Symbols Looks pretty crazy right? The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

Have you downloaded a copy of the Australian Welding Guide? The Australian Welding Guide is the ultimate guide when it comes to welding. WIA have been publishing the guide for many years. Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach.

Have you downloaded a copy of the Australian Welding Guide? The Australian Welding Guide is the ultimate guide when it comes to welding. WIA have been publishing the guide for many years. This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf

This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the The type of welding electrode used would decide the weld properties such as strength, ductility and corrosion resistance. The type to be used for a particular job depends upon the type of metal being welded, the amount of material to be added and the position of the work. The two general classes of electrodes are lightly coated and heavily coated. The heavily coated electrodes are normally

– 175 – –––––––––––– BASIC ARC AND GAS WELDING SYMBOLS Location of Welding Arrow (or Near) Side of Joint Other (or Far) Side of Joint Welding Processes. The type of joint to be created and the type of material to be used, among other considerations, will determine the type of welding process that will be used to complete the project.

Welding Handbook Ninth Edition Volume 1 WELDING SCIENCE AND TECHNOLOGY Prepared under the direction of the Welding Handbook Committee Cynthia L. Jenney Annette O’Brien Editors American Welding Society 550 N.W. LeJeune Road Miami, FL 33126 . ii Welding Handbook, Ninth Edition Volume 1 Welding Science and Technology Volume 2 Welding Processes—Part 1 Volume 3 Welding … This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, …

Щ†ШЄЩЉШ¬Ш© ШЁШШ« Ш§Щ„ШµЩ€Ш± Ш№Щ† ‪welding symbols‬‏ Welding in 2018

Welding symbols Welded joints types Design elements. Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below: A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop., This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the.

Types of Welding in Flowchart Mechanical Design Software

SnГmek 1 Гљstav strojГrenskГ© technologie ДЊVUT v Praze. NOTE: "fillet weld" = a triangular shaped weld in a corner Name three types of joints that use fillet welds? Welding Joint Design & Welding Symbols –Chapter #5, This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf.

NOTE: "fillet weld" = a triangular shaped weld in a corner Name three types of joints that use fillet welds? Welding Joint Design & Welding Symbols –Chapter #5 WELDING SYMBOLS. Special symbols are used on a drawing to specify where welds are to be located, the type of joint to be used, as well as the size and amount of …

Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below: A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop. Misunderstanding Welding Symbols: Part 1. 2 years ago. Welding symbol detail drawing with pencil and eyeglass. Sourced from AWS Learning. We’ve published several blogs over the years, and while we receive comments on all of them, we’ve noticed a steady stream of feedback on our blogs about welding symbols. Due to continued interest in these previously published blogs, we’ve decided to

Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach. The type of welding electrode used would decide the weld properties such as strength, ductility and corrosion resistance. The type to be used for a particular job depends upon the type of metal being welded, the amount of material to be added and the position of the work. The two general classes of electrodes are lightly coated and heavily coated. The heavily coated electrodes are normally

Types of welding position This chapter presents common types of welding position and various difficulties associated with them. Further, need for edge preparation and the rationale for selection of suitable groove design have also been presented. Keywords: Flat welding, horizontal welding, vertical and overhead welding, groove weld, edge preparation 23.1 Welding position The welding positions The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged – 175 – –––––––––––– BASIC ARC AND GAS WELDING SYMBOLS Location of Welding Arrow (or Near) Side of Joint Other (or Far) Side of Joint

Let’s take a look at how welding serves industrial fabrication as well as the different types of welding services. How Welding In General Serves Industrial Fabrication Welding is the process of securely joining two materials together using the process of coalescence and often also a filler material. Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals)

Let’s take a look at how welding serves industrial fabrication as well as the different types of welding services. How Welding In General Serves Industrial Fabrication Welding is the process of securely joining two materials together using the process of coalescence and often also a filler material. This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf

Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below: A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop. This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the

Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals) WELDING SYMBOLS. Special symbols are used on a drawing to specify where welds are to be located, the type of joint to be used, as well as the size and amount of …

Types of welding position This chapter presents common types of welding position and various difficulties associated with them. Further, need for edge preparation and the rationale for selection of suitable groove design have also been presented. Keywords: Flat welding, horizontal welding, vertical and overhead welding, groove weld, edge preparation 23.1 Welding position The welding positions Welding Handbook Ninth Edition Volume 1 WELDING SCIENCE AND TECHNOLOGY Prepared under the direction of the Welding Handbook Committee Cynthia L. Jenney Annette O’Brien Editors American Welding Society 550 N.W. LeJeune Road Miami, FL 33126 . ii Welding Handbook, Ninth Edition Volume 1 Welding Science and Technology Volume 2 Welding Processes—Part 1 Volume 3 Welding …

SnГmek 1 Гљstav strojГrenskГ© technologie ДЊVUT v Praze. Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl., This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf.

Welding symbols Welded joints types Design elements

welding scribd.com. Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals), This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the.

Welding symbols Welded joints types Design elements. Let’s take a look at how welding serves industrial fabrication as well as the different types of welding services. How Welding In General Serves Industrial Fabrication Welding is the process of securely joining two materials together using the process of coalescence and often also a filler material., Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach..

Types of Welding in Flowchart Mechanical Design Software

TYPES OF WELDING SYMBOLS PDF nagazumi.info. Have you downloaded a copy of the Australian Welding Guide? The Australian Welding Guide is the ultimate guide when it comes to welding. WIA have been publishing the guide for many years. Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below: A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop..

Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl. Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl.

Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below: A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop. The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

A symbol that contains a few lines, some weird shape, enough words, but so many information. Technical Articles. While there may be slight varieties in a different types of welding symbols, the syntax usually looks like this: The Elements of Welding Symbols Looks pretty crazy right? Welding Processes. The type of joint to be created and the type of material to be used, among other considerations, will determine the type of welding process that will be used to complete the project.

Welding symbols can therefore specify the welding without including all of the many possible details within the symbols. Simpler welding symbols are easier to add to a drawing and to interpret. Fewer errors are a benefit of this approach. WELDING SYMBOLS. Special symbols are used on a drawing to specify where welds are to be located, the type of joint to be used, as well as the size and amount of …

Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl. WELDING SYMBOLS. Special symbols are used on a drawing to specify where welds are to be located, the type of joint to be used, as well as the size and amount of …

Welding Handbook Ninth Edition Volume 1 WELDING SCIENCE AND TECHNOLOGY Prepared under the direction of the Welding Handbook Committee Cynthia L. Jenney Annette O’Brien Editors American Welding Society 550 N.W. LeJeune Road Miami, FL 33126 . ii Welding Handbook, Ninth Edition Volume 1 Welding Science and Technology Volume 2 Welding Processes—Part 1 Volume 3 Welding … This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, …

Types of welding joints There are five basic types of weld joints: Butt Joint: It is a joint between two materials lying in same plane. They are further of two types: a square butt joint( to join light sheet metals ) , a beveled butt joint( to join heavier pieces of metals) – 175 – –––––––––––– BASIC ARC AND GAS WELDING SYMBOLS Location of Welding Arrow (or Near) Side of Joint Other (or Far) Side of Joint

Diffternt types of. Welding Joints PRESENTED BY: DCRUST, MURTHAL Five Basic Welded Joints 1. Butt Joint 2. Corner Joint 3. T – Joint This type of geometric defect is generally caused by a setup/fit up problem, or trying to join plates of different thickness. Overlap The protrusion of weld metal beyond the weld toe or weld root. It is caused by poor welding techniques and can generally be overcome by an improved weld procedure. The overlap can be repaired by grinding off excess weld metal and surface grinding smoothly to the

The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged – 175 – –––––––––––– BASIC ARC AND GAS WELDING SYMBOLS Location of Welding Arrow (or Near) Side of Joint Other (or Far) Side of Joint

This engineering drawing present weld type symbols and fillet weld symbols. The weld type symbol is typically placed above or below the center of the reference line, … The type of current used in arc welding also plays an important role in welding. Consumable electrode processes such as shielded metal arc welding and gas metal arc welding generally use direct current, but the electrode can be charged

This sample was created in ConceptDraw PRO diagramming and vector drawing software using the Flowcharts solution from the What is a Diagram area of ConceptDraw Solution Park. This sample shows the Flowchart that displays the solid-state welding processes, the types of welding. Welding Types And Symbols Pdf Each type of joint has its own symbol. The basic weld symbols are shown in Table-10.3.1. Table10.3.1: Basic weld types and their symbols Sl.

The aim of this experiment is to investigate the effect of chewing gum on working memory performance, thus evaluating whether chewing gum enhances working memory performance. Memory is the ability to retain and recall information and past experiences in the human brain. Experiments on memory recall and chewing gum pdf Coongulla In our study we focused on an audio task that involved short-term memory recall to see if chewing gum would improve concentration; especially in the latter stages of the task,” said co-study