Application Note Monitoring Steam Purity in Power Plants Steam Plant Operation, McGraw-Hill.[ This is a basic book on plant equipment. It illustrates various power plant components and describes their use and operation.] Biographical Sketch Robin Chaplin obtained a B.Sc. and M.Sc. in mechanical engineering from University of Cape Town in . UNESCO – EOLSS SAMPLE CHAPTERS THERMAL POWER PLANTS - Steam Turbine Components and Systems …

STEAM TURBINE FOR POWER PLANT UNIT WITH SUPERCRITICAL .pdf

Combined-Cycle Power Plant – How it Works GE Power. a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made., a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made..

The Power Plant is a combined heat and power plant facility that generates about one-third of the university’s electric power needs. Steam produced by the plant is used for: study on combined cycle gas and steam turbine power plants, the typical steam turbine outlet pressure in con- densing mode ranges from 0.03 to 0.25 bar [16] while Aref [17] in his work on development of framework for

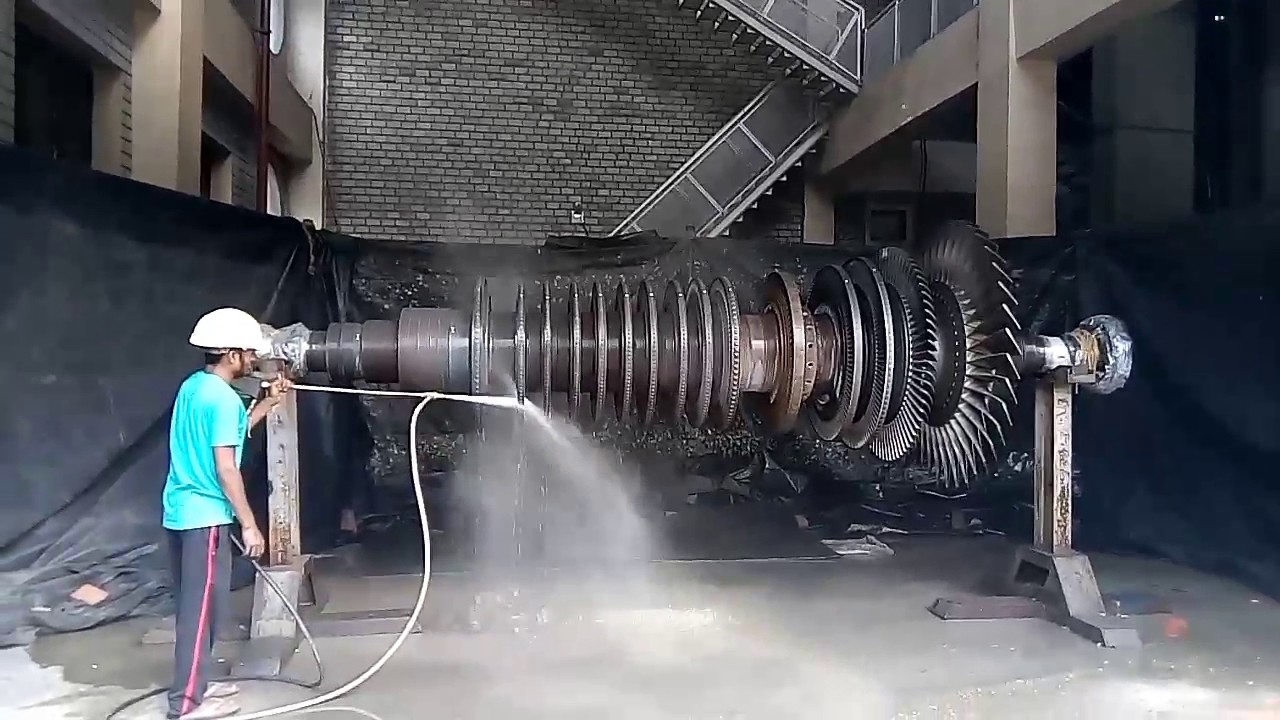

STEAM CONSUMPTION Steam consumption of steam turbine is depending to required output power and efficiency of the turbine. Efficiency will depend on turbine size or rotor diameter. Very high steam temperature will decrease strength of material of turbine blades and cause limitation of design speed. Figure 9.STEAM TURBINE 10 VII. Lower speed and high enthalpy differential will reduce efficiency pressure at the turbine throttle valve inlet plus the main steam line pressure drop (between the superheater outlet and turbine throttle valve inlet at the maximum continuous rating of the boiler) rounded to the next higher unit of 5 psi (34 kPa gage).

Highly-reliable Design Technology of Steam Turbine for Nuclear Power Plant 104 in the turbine and the vibrational stresses due to the forces induced by the steam acting on the blade. 1. Introduction A steam turbine defined as a form of heat engine in which the energy of the steam is transformed into kinetic energy by expansion through nozzles, and the kinetic energy of …

The combination of torque and speed is the output power of the turbine. Steam turbines used as process drivers are usually required to operate over a range of speeds, in contrast to a turbine used to drive an electric generator which runs at nearly Capital and O&M Costs. Major subsystems required for a complete steam turbine CHP plant include a boiler . or HRSG, steam loop, and a steam turbine.

Fig. 1.3 shows the world power generation of steam turbine power plants calculated using world net electricity generation by fuel , and an assumption of a power plant configuration ratio by fuel (power generation ratio of steam turbines, gas turbines, hydro turbines, wind turbines, PVs, and others, by each fuel). The data for 2007 and 2012 are factual, while the data for 2020–2040 are Typical Arrangement of Steam Turbine Condenser Large power plant condensers are usually 'shell and tube' heat These types of condensers are also classified: Condenser Cooling System . Other types of condensers are: • Plate types consisting of a series of parallel plates that provide paths for the steam and the cooling water. Plate condensers are used mainly for smaller power plants; and

steam power plants. Therefore, it is very important to ensure that the plants are working with maximum efficiency. Thermodynamic analysis of the thermal power plant has been undertaken to enhance the efficiency and reliability of steam power plants. Most of the power plants are designed by the energetic performance criteria based on first law of thermodynamics only. The real useful energy loss Documents Similar To STEAM TURBINE FOR POWER PLANT UNIT WITH SUPERCRITICAL .pdf

a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made. steam power plant a steam turbine is used for extracting the heat from the steam and turning it into work. The turbine usually drives a generator that turns the work from the turbine into electricity. The steam, used by the turbine, can be recycled by cooling it until it condensates into water and then return it as feedwater to the boiler. The condenser, where the steam is condensed, is a heat

Highly-reliable Design Technology of Steam Turbine for Nuclear Power Plant 104 in the turbine and the vibrational stresses due to the forces induced by the steam acting on the blade. A combined-cycle power plant uses both a gas and a steam turbine together to produce up to 50 percent more electricity from the same fuel than a traditional simple-cycle plant. The waste heat from the gas turbine is routed to the nearby steam turbine, which generates extra power.

a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made. – The trend in power plant design is to generate power with a gas turbine and use the exhaust heat to generate steam that provides additional power through a steam turbine.

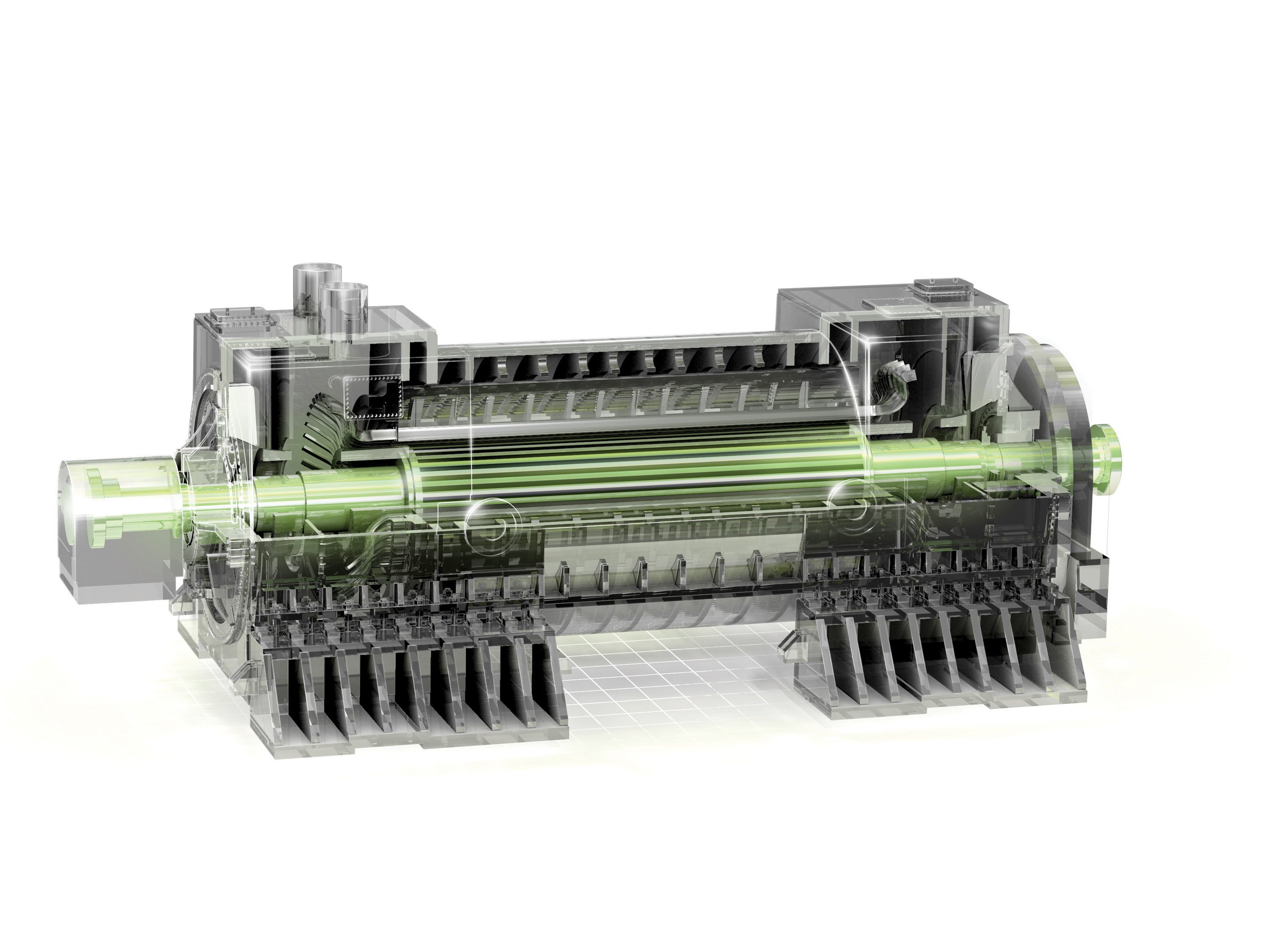

to the steam turbine, which generates electrical power. In all cycles, surplus heat can be stored in large storage tanks and used to extend the running hours of the steam turbine during times with- out sun radiation. Siemens turbine technology can fit all of these concentrated solar power (CSP) concepts. Parabolic trough collectors Linear Fresnel collector panels Solar tower plant Solar field As a market leader for industrial steam turbines, we offer a comprehensive range of reliable and versatile steam turbines for the power output range from 2 to 250 MW. Our industrial steam turbines are designed for easy constructability, fast start-up and economical operation.

Industrial Steam Turbines The comprehensive product range from 2 to 250 megawatts Industrial Power siemens.com / energy / seamturbinest Scan the QR code with the QR code reader in your mobile! A Full Range of World-class Industrial Steam Turbines Whatever your need for a prime mover, Siemens can provide you with versatile, reliable and proven indus-trial steam turbines. A world leader in steam Steam Plant Operation, McGraw-Hill.[ This is a basic book on plant equipment. It illustrates various power plant components and describes their use and operation.] Biographical Sketch Robin Chaplin obtained a B.Sc. and M.Sc. in mechanical engineering from University of Cape Town in . UNESCO – EOLSS SAMPLE CHAPTERS THERMAL POWER PLANTS - Steam Turbine Components and Systems …

CHAPTER 4 Steam power plants WIT Press

Introduction to steam turbines for power plants. TURBINE In a hydroelectric power plant, wate r, flowing from a higher level to a lower level, travels through the metal blades of a water turbine, causing the rotor of the electrical generator to spin and produce electricity. Reactor Concepts Manual Nuclear Power for Electrical Generation USNRC Technical Training Center 1-5 0703 Main Condenser Main Turbine Electric Generator Throttle Valve, Documents Similar To STEAM TURBINE FOR POWER PLANT UNIT WITH SUPERCRITICAL .pdf.

Introduction to steam turbines for power plants

STEAM TURBINE.pdf Turbine Steam. STEAM CONSUMPTION Steam consumption of steam turbine is depending to required output power and efficiency of the turbine. Efficiency will depend on turbine size or rotor diameter. Very high steam temperature will decrease strength of material of turbine blades and cause limitation of design speed. Figure 9.STEAM TURBINE 10 VII. Lower speed and high enthalpy differential will reduce efficiency https://en.wikipedia.org/wiki/Combined_cycle In a steam power plant, power is generated by the turbine generators that utilize steam produced in the boilers. The specific design of the steam cycle and its operating conditions (primarily, the steam ….

1. Introduction A steam turbine defined as a form of heat engine in which the energy of the steam is transformed into kinetic energy by expansion through nozzles, and the kinetic energy of … Fig. 1.3 shows the world power generation of steam turbine power plants calculated using world net electricity generation by fuel , and an assumption of a power plant configuration ratio by fuel (power generation ratio of steam turbines, gas turbines, hydro turbines, wind turbines, PVs, and others, by each fuel). The data for 2007 and 2012 are factual, while the data for 2020–2040 are

Figure 1 - Simplified water-steam cycle in a power plant showing the major ways contamination enters the system. Once contaminants are in the system, they have the potential to enter the steam and be carried into the turbine. As long as the contamination is below a critical level, impurities remain in the steam and travel through the turbine without causing trouble. However, higher levels of Nuclear Power Plants The Turbine Island Philippe Anglaret VP Business Development , Alstom Nuclear Nuclear Island + Turbine Island + BoP = Nuclear Power Plant Balance of Plant (including Alstom Grid) p.4 Credits to EDF Alstom in Nuclear Turbine Islands based on ARABELLE™ technology. p.5 30% of all the world’s nuclear plants have an Alstom steam turbine 55 years of experience : 136

Fig. 1.3 shows the world power generation of steam turbine power plants calculated using world net electricity generation by fuel , and an assumption of a power plant configuration ratio by fuel (power generation ratio of steam turbines, gas turbines, hydro turbines, wind turbines, PVs, and others, by each fuel). The data for 2007 and 2012 are factual, while the data for 2020–2040 are I - Power Plant Steam Cycle Theory - R.A. Chaplin This has an effect on the expansi on of the steam in the turbine and ultimately on the power output per unit mass of steam and hence the overall cycle efficiency. 1. Cycle Efficienies 1.2. Introduction Early reciprocating steam engines and most steam locomotives were designed to operate on an open cycle where the exhaust steam was

Steam Plant Operation, McGraw-Hill.[ This is a basic book on plant equipment. It illustrates various power plant components and describes their use and operation.] Biographical Sketch Robin Chaplin obtained a B.Sc. and M.Sc. in mechanical engineering from University of Cape Town in . UNESCO – EOLSS SAMPLE CHAPTERS THERMAL POWER PLANTS - Steam Turbine Components and Systems … plants based on steam turbine technology and very low-cost fuel. Combined-cycle plants use the high volume and temperature in the exhaust of gas turbines in a boiler to make steam suitable for steam turbines and other industrial and commercial applications. Modern combined cycles have achieved efficiencies around 60 percent for elec-trical power production only and over 85 percent for

18/12/2018 · Dedicated to power plants, power generation, supercritical, and heating plants as well as steam boilers, steam turbine generators, gas turbines or combustion turbines, hrsg, steam heating, pressure vessels, steam line, including ASME questions and more. Remember the forum is made up of volunteers from experts to beginners. The Power Plant is a combined heat and power plant facility that generates about one-third of the university’s electric power needs. Steam produced by the plant is used for:

output steam turbines for power generation application are designed primarily with the requirements of utilities and heating facilities in mind. We can tailor our wide range of medium and large output steam turbines to fit the requirements of your project. • One, two and multiple-core units, with or without steam reheating • Speeds of 3,000 rpm or 3,600 rpm • Pure condensing, condensing a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made.

output steam turbines for power generation application are designed primarily with the requirements of utilities and heating facilities in mind. We can tailor our wide range of medium and large output steam turbines to fit the requirements of your project. • One, two and multiple-core units, with or without steam reheating • Speeds of 3,000 rpm or 3,600 rpm • Pure condensing, condensing study on combined cycle gas and steam turbine power plants, the typical steam turbine outlet pressure in con- densing mode ranges from 0.03 to 0.25 bar [16] while Aref [17] in his work on development of framework for

TURBINE In a hydroelectric power plant, wate r, flowing from a higher level to a lower level, travels through the metal blades of a water turbine, causing the rotor of the electrical generator to spin and produce electricity. Reactor Concepts Manual Nuclear Power for Electrical Generation USNRC Technical Training Center 1-5 0703 Main Condenser Main Turbine Electric Generator Throttle Valve Steam Turbines for Geothermal Power Plants SST-400 GEO and SST-500 GEO with Power Output up to 120 MW Industrial Power Scan the QR code with the QR code reader in your mobile! 3 Geothermal Energy Electrical power production from geothermal energy is a mature technology. The first geothermal power plant at Larderello in Italy was constructed more than 100 years ago, and the same resource

pressure at the turbine throttle valve inlet plus the main steam line pressure drop (between the superheater outlet and turbine throttle valve inlet at the maximum continuous rating of the boiler) rounded to the next higher unit of 5 psi (34 kPa gage). power plant (CCPP) or combined cycle gas turbine (CCGT) plant, as gas turbine generator generates electricity and waste heat is used to make steam to generate additional electricity via a steam turbine, this last step enhances the efficiency of

Capital and O&M Costs. Major subsystems required for a complete steam turbine CHP plant include a boiler . or HRSG, steam loop, and a steam turbine. power plant (CCPP) or combined cycle gas turbine (CCGT) plant, as gas turbine generator generates electricity and waste heat is used to make steam to generate additional electricity via a steam turbine, this last step enhances the efficiency of

Almar Gunnarsson, 2013, Maintenance of the steam turbines at Hellisheiði power plant , Master’s thesis, Faculty of Industrial Engineering, Mechanical Engineering and Computer science, University of … Steam parameters such as temperature and pressure required for CSP plants are lower than those of fossil fired power plants and higher than the parameters of nuclear power plants. As a supplier of both fossil and nuclear steam turbines Siemens experience covers also the CSP thermodynamic range. This paper describes technology and performance of the SST-5000 series optimized for application in

University of Iowa Power Plant

Power Plants Steam and Gas Turbines WebQuest. Steam turbine power plants operate on "Rankine cycle" for the production of electric power. If the steam from the waste heat boiler is used for process or space heating, the term "cogeneration" is the more correct terminology (simultaneous production of electric and heat energy). Steam turbine plants generally have a history of achieving up to 95% availability and can operate for more than a, a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made..

Steam turbines Power Generation Energy Technology

Industrial Power Steam Turbines for Geothermal Power Plants. Modern Combined Cycle Gas Turbine (CCGT) plants, in which the thermodynamic cycle of consists of two power plant cycles (e.g. the Brayton cycle and the Rankine cycle), can achieve a thermal efficiency of around 55%, in contrast to a single cycle steam power plant which is …, High-pressure steam from these boilers can be used to generate additional electric power with steam turbines, a configuration called a combined cycle. A simple cycle gas turbine can achieve energy conversion efficiencies ranging between 20 and 35 percent..

plants based on steam turbine technology and very low-cost fuel. Combined-cycle plants use the high volume and temperature in the exhaust of gas turbines in a boiler to make steam suitable for steam turbines and other industrial and commercial applications. Modern combined cycles have achieved efficiencies around 60 percent for elec-trical power production only and over 85 percent for 1. Introduction A steam turbine defined as a form of heat engine in which the energy of the steam is transformed into kinetic energy by expansion through nozzles, and the kinetic energy of …

Industrial Steam Turbines The comprehensive product range from 2 to 250 megawatts Industrial Power siemens.com / energy / seamturbinest Scan the QR code with the QR code reader in your mobile! A Full Range of World-class Industrial Steam Turbines Whatever your need for a prime mover, Siemens can provide you with versatile, reliable and proven indus-trial steam turbines. A world leader in steam The steam turbine of 51.5 MW power output, turbine condenser, generator and turbine controls have been ordered. The equipments will be installed at Obayashi Kamisu biomass power plant in Kamisu city, Ibaraki prefecture, Japan.

© ALSTOM 2012. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be Modern Combined Cycle Gas Turbine (CCGT) plants, in which the thermodynamic cycle of consists of two power plant cycles (e.g. the Brayton cycle and the Rankine cycle), can achieve a thermal efficiency of around 55%, in contrast to a single cycle steam power plant which is …

Steam emissions from naturally occurring aquifers are also used to power steam turbine power plants. The Steam Turbine (Prime Mover) The first practical steam turbines were made by Gustaf de Laval 1882 and Charles Parsons in the 1884. Diagram of de Laval's Steam Impulse Turbine 1882 . Steam enters on one side of the turbine rotor through the nozzles, pointing at the surface of the turbine a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made.

Figure 1 - Simplified water-steam cycle in a power plant showing the major ways contamination enters the system. Once contaminants are in the system, they have the potential to enter the steam and be carried into the turbine. As long as the contamination is below a critical level, impurities remain in the steam and travel through the turbine without causing trouble. However, higher levels of Nuclear Power Plants The Turbine Island Philippe Anglaret VP Business Development , Alstom Nuclear Nuclear Island + Turbine Island + BoP = Nuclear Power Plant Balance of Plant (including Alstom Grid) p.4 Credits to EDF Alstom in Nuclear Turbine Islands based on ARABELLE™ technology. p.5 30% of all the world’s nuclear plants have an Alstom steam turbine 55 years of experience : 136

Modern Combined Cycle Gas Turbine (CCGT) plants, in which the thermodynamic cycle of consists of two power plant cycles (e.g. the Brayton cycle and the Rankine cycle), can achieve a thermal efficiency of around 55%, in contrast to a single cycle steam power plant which is … Steam parameters such as temperature and pressure required for CSP plants are lower than those of fossil fired power plants and higher than the parameters of nuclear power plants. As a supplier of both fossil and nuclear steam turbines Siemens experience covers also the CSP thermodynamic range. This paper describes technology and performance of the SST-5000 series optimized for application in

to the steam turbine, which generates electrical power. In all cycles, surplus heat can be stored in large storage tanks and used to extend the running hours of the steam turbine during times with- out sun radiation. Siemens turbine technology can fit all of these concentrated solar power (CSP) concepts. Parabolic trough collectors Linear Fresnel collector panels Solar tower plant Solar field High-pressure steam from these boilers can be used to generate additional electric power with steam turbines, a configuration called a combined cycle. A simple cycle gas turbine can achieve energy conversion efficiencies ranging between 20 and 35 percent.

a functional steam turbine power plant. A comparison of real world operating characteristics A comparison of real world operating characteristics to that of the ideal Rankine power cycle will be made. plants based on steam turbine technology and very low-cost fuel. Combined-cycle plants use the high volume and temperature in the exhaust of gas turbines in a boiler to make steam suitable for steam turbines and other industrial and commercial applications. Modern combined cycles have achieved efficiencies around 60 percent for elec-trical power production only and over 85 percent for

Advances in Steam Turbines for Modern Power Plants provides an authoritative review of steam turbine design optimization, analysis and measurement, the development of steam turbine blades, and other critical components, including turbine retrofitting and steam turbines for renewable power plants. pressure at the turbine throttle valve inlet plus the main steam line pressure drop (between the superheater outlet and turbine throttle valve inlet at the maximum continuous rating of the boiler) rounded to the next higher unit of 5 psi (34 kPa gage).

steam power plant a steam turbine is used for extracting the heat from the steam and turning it into work. The turbine usually drives a generator that turns the work from the turbine into electricity. The steam, used by the turbine, can be recycled by cooling it until it condensates into water and then return it as feedwater to the boiler. The condenser, where the steam is condensed, is a heat Steam Plant Operation, McGraw-Hill.[ This is a basic book on plant equipment. It illustrates various power plant components and describes their use and operation.] Biographical Sketch Robin Chaplin obtained a B.Sc. and M.Sc. in mechanical engineering from University of Cape Town in . UNESCO – EOLSS SAMPLE CHAPTERS THERMAL POWER PLANTS - Steam Turbine Components and Systems …

STEAM TURBINE.pdf Turbine Steam

University of Iowa Power Plant. The kind of turbine most often used in a power plant is the steam turbine, which drives the electrical generator and auxiliary equipment. The steam turbine con-, to the steam turbine, which generates electrical power. In all cycles, surplus heat can be stored in large storage tanks and used to extend the running hours of the steam turbine during times with- out sun radiation. Siemens turbine technology can fit all of these concentrated solar power (CSP) concepts. Parabolic trough collectors Linear Fresnel collector panels Solar tower plant Solar field.

University of Iowa Power Plant. Steam emissions from naturally occurring aquifers are also used to power steam turbine power plants. The Steam Turbine (Prime Mover) The first practical steam turbines were made by Gustaf de Laval 1882 and Charles Parsons in the 1884. Diagram of de Laval's Steam Impulse Turbine 1882 . Steam enters on one side of the turbine rotor through the nozzles, pointing at the surface of the turbine, world market leader in steam turbines for CSP plants, and has more than 20 years of experience with steam turbines for daily cycling. The SST-700 steam turbine in the US King City power plant is a good example of this. Parabolic trough technology With operational experience of more than 20 years in commercial installations, the parabolic trough technology has proven its reliability, showing.

Power Plants Steam and Gas Turbines WebQuest

Using Steam in the Power Plant TPC Training. UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS APPROVED FOR PUBLIC RELEASE; DISTRIBUTION UNLIMITED . UFC 3-540-02N 16 January 2004 UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS Any copyrighted material included in this UFC is identified at its point of use. Use of the copyrighted material apart from this UFC must have the permission of … https://en.m.wikipedia.org/wiki/Combined_gas_and_steam Educ. Sci. 2012, 2 181 1. Introduction Since 2010, the main objective of the Bologna Process has been to create a European Higher Education Area to standardize academic degrees and quality standards in European countries..

The combination of torque and speed is the output power of the turbine. Steam turbines used as process drivers are usually required to operate over a range of speeds, in contrast to a turbine used to drive an electric generator which runs at nearly A combined-cycle power plant uses both a gas and a steam turbine together to produce up to 50 percent more electricity from the same fuel than a traditional simple-cycle plant. The waste heat from the gas turbine is routed to the nearby steam turbine, which generates extra power.

The combination of torque and speed is the output power of the turbine. Steam turbines used as process drivers are usually required to operate over a range of speeds, in contrast to a turbine used to drive an electric generator which runs at nearly The kind of turbine most often used in a power plant is the steam turbine, which drives the electrical generator and auxiliary equipment. The steam turbine con-

Capital and O&M Costs. Major subsystems required for a complete steam turbine CHP plant include a boiler . or HRSG, steam loop, and a steam turbine. Steam turbine power plants operate on "Rankine cycle" for the production of electric power. If the steam from the waste heat boiler is used for process or space heating, the term "cogeneration" is the more correct terminology (simultaneous production of electric and heat energy). Steam turbine plants generally have a history of achieving up to 95% availability and can operate for more than a

In response to the growing demand of new nuclear power plants, Siemens is implementing and further developing a modular platform of half speed steam turbines and generators covering the most relevant power range from 1000 MWe up to 1900 MWe. The following product will be described in this paper: Siemens Steam Turbine Generator Packages: SST-9000 series for nuclear power plants; … UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS APPROVED FOR PUBLIC RELEASE; DISTRIBUTION UNLIMITED . UFC 3-540-02N 16 January 2004 UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS Any copyrighted material included in this UFC is identified at its point of use. Use of the copyrighted material apart from this UFC must have the permission of …

I - Power Plant Steam Cycle Theory - R.A. Chaplin This has an effect on the expansi on of the steam in the turbine and ultimately on the power output per unit mass of steam and hence the overall cycle efficiency. 1. Cycle Efficienies 1.2. Introduction Early reciprocating steam engines and most steam locomotives were designed to operate on an open cycle where the exhaust steam was power plant (CCPP) or combined cycle gas turbine (CCGT) plant, as gas turbine generator generates electricity and waste heat is used to make steam to generate additional electricity via a steam turbine, this last step enhances the efficiency of

Steam Turbines for Geothermal Power Plants SST-400 GEO and SST-500 GEO with Power Output up to 120 MW Industrial Power Scan the QR code with the QR code reader in your mobile! 3 Geothermal Energy Electrical power production from geothermal energy is a mature technology. The first geothermal power plant at Larderello in Italy was constructed more than 100 years ago, and the same resource UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS APPROVED FOR PUBLIC RELEASE; DISTRIBUTION UNLIMITED . UFC 3-540-02N 16 January 2004 UNIFIED FACILITIES CRITERIA (UFC) STEAM POWER PLANTS Any copyrighted material included in this UFC is identified at its point of use. Use of the copyrighted material apart from this UFC must have the permission of …

steam power plants. Therefore, it is very important to ensure that the plants are working with maximum efficiency. Thermodynamic analysis of the thermal power plant has been undertaken to enhance the efficiency and reliability of steam power plants. Most of the power plants are designed by the energetic performance criteria based on first law of thermodynamics only. The real useful energy loss Figure 1 - Simplified water-steam cycle in a power plant showing the major ways contamination enters the system. Once contaminants are in the system, they have the potential to enter the steam and be carried into the turbine. As long as the contamination is below a critical level, impurities remain in the steam and travel through the turbine without causing trouble. However, higher levels of

The combination of torque and speed is the output power of the turbine. Steam turbines used as process drivers are usually required to operate over a range of speeds, in contrast to a turbine used to drive an electric generator which runs at nearly I - Power Plant Steam Cycle Theory - R.A. Chaplin This has an effect on the expansi on of the steam in the turbine and ultimately on the power output per unit mass of steam and hence the overall cycle efficiency. 1. Cycle Efficienies 1.2. Introduction Early reciprocating steam engines and most steam locomotives were designed to operate on an open cycle where the exhaust steam was

steam power plant a steam turbine is used for extracting the heat from the steam and turning it into work. The turbine usually drives a generator that turns the work from the turbine into electricity. The steam, used by the turbine, can be recycled by cooling it until it condensates into water and then return it as feedwater to the boiler. The condenser, where the steam is condensed, is a heat Steam Turbines for Geothermal Power Plants SST-400 GEO and SST-500 GEO with Power Output up to 120 MW Industrial Power Scan the QR code with the QR code reader in your mobile! 3 Geothermal Energy Electrical power production from geothermal energy is a mature technology. The first geothermal power plant at Larderello in Italy was constructed more than 100 years ago, and the same resource

world market leader in steam turbines for CSP plants, and has more than 20 years of experience with steam turbines for daily cycling. The SST-700 steam turbine in the US King City power plant is a good example of this. Parabolic trough technology With operational experience of more than 20 years in commercial installations, the parabolic trough technology has proven its reliability, showing Steam turbines are suitable for large thermal power plants. They are made in a variety of sizes up to 1.5 GW (2,000,000 hp) turbines used to generate electricity. They are made in a variety of sizes up to 1.5 GW (2,000,000 hp) turbines used to generate electricity.

Figure 1 - Simplified water-steam cycle in a power plant showing the major ways contamination enters the system. Once contaminants are in the system, they have the potential to enter the steam and be carried into the turbine. As long as the contamination is below a critical level, impurities remain in the steam and travel through the turbine without causing trouble. However, higher levels of STEAM CONSUMPTION Steam consumption of steam turbine is depending to required output power and efficiency of the turbine. Efficiency will depend on turbine size or rotor diameter. Very high steam temperature will decrease strength of material of turbine blades and cause limitation of design speed. Figure 9.STEAM TURBINE 10 VII. Lower speed and high enthalpy differential will reduce efficiency